PVC Heat Stabilizers: Essential for Durable, Long-Lasting Plastics

In today’s plastics industry, durability is a non-negotiable feature. From construction and automotive parts to household items and packaging, plastic products are expected to perform under pressure—literally and figuratively. One of the key additives enabling this resilience is the heat stabilizer. These compounds play a vital role in preserving the structural integrity and appearance of plastics when exposed to heat, making them indispensable in modern manufacturing.

What Are PVC Heat Stabilizers?

Heat stabilizers are chemical agents used to protect thermoplastics, especially PVC (polyvinyl chloride), from degrading at high temperatures. During the production process, plastics often undergo intense heat through extrusion, molding, or calendaring. Without stabilizers, the material is prone to discoloration, brittleness, and cracking due to the breakdown of molecular chains. Heat stabilizers counteract these effects by absorbing thermal energy and neutralizing harmful byproducts like hydrochloric acid (HCl) released from PVC during heating.

How PVC Heat Stabilizers Work

There are several types of heat stabilizers used depending on the application. Calcium-Zinc (Ca-Zn) stabilizers are growing in popularity due to their non-toxic, environmentally friendly nature. They’re ideal for sensitive applications like food-grade packaging, toys, and medical devices. Tin-based stabilizers offer excellent clarity and are often used in transparent films and bottles. While lead stabilizers were once common, their use has significantly declined due to health and environmental concerns, with regulations pushing for safer alternatives.

Why They Matter: Key Benefits

The benefits of heat stabilizers are multifaceted. First, they enhance thermal resistance, helping plastic products withstand both processing and long-term usage at elevated temperatures. Second, they prevent discoloration, ensuring that the plastic retains its original look and doesn’t yellow or fade over time. Additionally, they help maintain the mechanical strength of the product, keeping it flexible, tough, and durable. Lastly, by improving processability, they allow manufacturers to achieve better consistency and throughput in production.

Heat stabilizers are used across a wide range of industries. In construction, they are essential in making durable PVC pipes, window frames, and siding. In the electrical sector, they help insulate wires and cables. They also play a crucial role in the medical field, especially in IV tubing and blood bags, and in packaging, where appearance and safety are paramount. Each application requires a tailored stabilizer formulation to meet industry-specific standards and performance requirements.

Eco-Friendly Alternatives at Pangrui

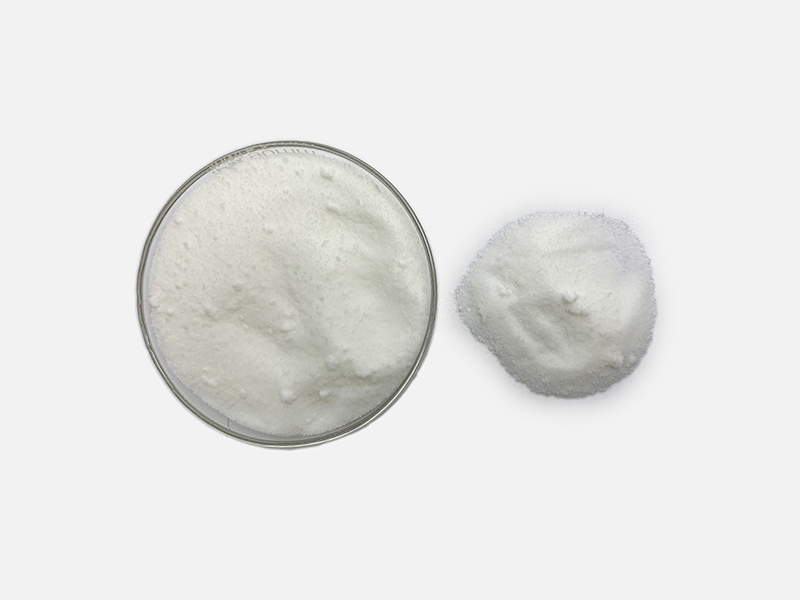

At Jiangsu Pangrui New Materials Co., Ltd., we recognize the growing demand for sustainable, high-performance stabilizers. Our calcium-zinc heat stabilizers provide an eco-friendly solution without sacrificing quality. They comply with global environmental regulations such as RoHS and REACH, making them suitable for use in industries that prioritize health and safety. As more manufacturers seek non-toxic alternatives, our stabilizers offer a competitive edge in responsible production.

Conclusion

In conclusion, heat stabilizers may be behind the scenes, but their impact on the final product is undeniable. From extending product lifespan to enhancing visual appeal and structural integrity, they are a critical part of every plastic formulation. With a growing emphasis on environmental safety, companies like Jiangsu Pangrui New Materials Co., Ltd. are leading the charge in delivering reliable, innovative, and compliant heat stabilizer solutions for manufacturers worldwide.