Creating the Perfect Formula: The Art and Science of PVC Product Development

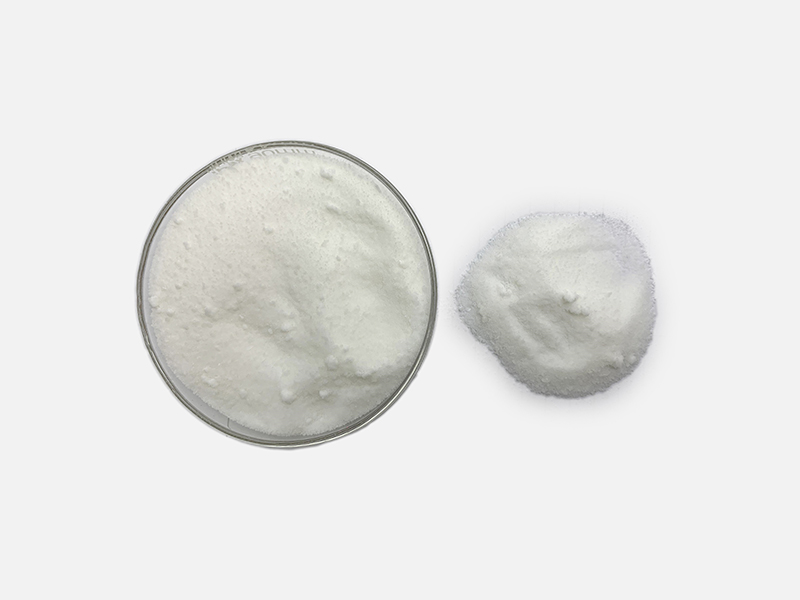

Behind every high-quality PVC product lies a carefully engineered formula that balances performance, durability, safety, and cost. PVC product development is not simply a matter of mixing raw materials—it is a precise combination of scientific knowledge, practical experience, and continuous innovation. Creating the perfect PVC formula requires a deep understanding of material behavior, processing conditions, and end-use requirements. It is both an art and a science, and mastering it is key to delivering reliable and competitive PVC solutions in today’s demanding markets. The foundation of any PVC product begins with the selection of PVC resin powder. Different resin grades offer varying molecular weights, particle sizes, and porosity levels, all of which directly influence processing behavior and final product performance. Choosing the right resin determines how the material melts, flows, and fuses during production. For rigid applications such as pipes, profiles, and panels, high-strength resin grades are preferred, while flexible products like cables, films, and hoses require resins that respond well to plasticizers. This initial choice sets the stage for the entire formulation process.

Heat stabilizers play a critical role in PVC product development. PVC is sensitive to heat, and without proper stabilization, it can degrade during processing, leading to discoloration, loss of mechanical strength, and reduced lifespan. The right heat stabilizer protects the PVC structure during extrusion, injection molding, or calendaring, ensuring consistent quality and long-term stability. Selecting the appropriate type and dosage of stabilizer is a precise task, as it must match the processing temperature, equipment, and application requirements while meeting regulatory and environmental standards. Plasticizers are another essential component, especially for flexible PVC products. They determine the softness, elasticity, and feel of the final material. The challenge lies in achieving the desired flexibility without compromising durability, migration resistance, or safety. Different applications demand different plasticizer characteristics—medical tubing, automotive interiors, and consumer goods all have unique performance and compliance requirements. Fine-tuning plasticizer selection and ratios is where experience and technical expertise truly make a difference.

Lubricants and processing aids may seem minor, but they are vital to achieving smooth and efficient production. Internal and external lubricants control friction during processing, prevent sticking, and improve surface finish. Proper lubrication ensures stable processing conditions, reduces equipment wear, and enhances productivity. An imbalance in lubricant formulation can lead to defects such as poor surface quality, uneven thickness, or unstable output, making this aspect of formulation both delicate and essential. Pigments and optical brighteners bring visual identity and functional benefits to PVC products. Color consistency, brightness, and weather resistance are critical, especially for construction materials, consumer products, and outdoor applications. Organic and inorganic pigments must be carefully selected to ensure compatibility with PVC and resistance to heat and UV exposure. Optical brighteners enhance appearance by improving whiteness and brightness, contributing to premium product quality. Achieving the perfect visual result while maintaining material stability requires careful formulation and testing.

Foaming agents, such as lubricant microsphere foaming agents, introduce another layer of complexity and opportunity. In applications where lightweight materials are desired, foamed PVC offers excellent performance with reduced material usage. Controlling cell structure, density, and surface quality demands precise formulation and processing control. When executed correctly, foamed PVC products provide excellent insulation, lower transportation costs, and improved sustainability without sacrificing strength. Conductive PVC formulations add yet another dimension to PVC product development. By incorporating conductive fillers such as conductive carbon black or ultra-nano conductive carbon black, PVC can be transformed from an insulating material into one that dissipates static or conducts electricity. Achieving stable conductivity while maintaining mechanical performance requires advanced formulation knowledge and precise dispersion techniques. This balance is crucial for applications in electronics, automotive components, and industrial safety products.

Testing and validation are where science truly meets reality. Laboratory testing evaluates thermal stability, mechanical strength, flexibility, conductivity, and aging resistance, while real-world trials ensure the formula performs under actual production and usage conditions. Adjustments are often necessary, as small changes in formulation can significantly affect performance. This iterative process is essential for refining formulas and achieving consistent, high-quality results. At Jiangsu Pangrui New Materials Co., Ltd., PVC product development is driven by a commitment to precision, innovation, and customer success. By providing optimized formula ratios, high-quality raw materials, free samples, and technical support, the company helps customers move from concept to production with confidence. This collaborative approach ensures that each PVC formula is tailored to specific applications, processing methods, and market demands.

Creating th perfect PVC formula is not about following a fixed recipe—it is about understanding the interaction between materials, machinery, and application needs. It requires scientific expertise, practical experience, and a willingness to innovate. As industries continue to demand higher performance, greater sustainability, and more customized solutions, the art and science of PVC product development will remain at the heart of material innovation, shaping products that are reliable, efficient, and ready for the future.