Building for the Future: How PVC Is Used in Sustainable Construction Solutions

PVC has long been recognized as one of the most versatile materials in modern manufacturing, but in recent years, it has gained increasing attention as a key contributor to sustainable construction. As global industries move toward greener practices and stricter environmental standards, the construction sector faces growing pressure to adopt materials that are durable, energy-efficient, and environmentally responsible. PVC (Polyvinyl Chloride), with its unique combination of performance and sustainability advantages, is playing a vital role in building the future of sustainable architecture and infrastructure. One of the primary reasons PVC is becoming central to sustainable construction is its exceptional durability. Buildings are long-term assets, and the materials used must withstand decades of environmental stress, including moisture, temperature changes, chemicals, and physical wear. PVC offers outstanding resistance to corrosion, weathering, and abrasion, making it ideal for applications such as window profiles, piping systems, flooring, roofing membranes, and insulation layers. Its long service life significantly reduces the need for frequent replacement, contributing to lower resource consumption and reduced waste generation over time.

Energy efficiency is another critical factor where PVC shines. Modern PVC materials can be formulated to provide excellent thermal insulation properties, helping buildings maintain stable indoor temperatures and reducing the energy required for heating and cooling. For example, PVC window frames have much lower thermal conductivity than aluminum, which directly translates to reduced energy consumption and lower utility costs. By enhancing the overall energy performance of buildings, PVC plays an essential role in meeting global goals for carbon reduction and sustainable urban development. In addition to energy efficiency, PVC contributes to water conservation and management—two essential components of sustainable construction. PVC piping systems, widely used for water distribution, drainage, and sewage networks, offer superior performance compared to traditional materials. They are lightweight, leak-resistant, and easy to install, reducing the risk of water loss and minimizing maintenance needs.

Their smooth internal surfaces ensure high flow efficiency, lowering the energy required to transport water. These advantages make PVC pipes a preferred choice in both residential and large-scale urban infrastructure projects aimed at improving long-term water sustainability. Sustainability in construction also depends on material recyclability, and PVC excels in this area. Unlike many composite materials that are difficult or impossible to recycle, PVC can be collected, reprocessed, and reused in new applications. Recycled PVC finds its way into construction profiles, flooring materials, pipes, and decorative elements. By supporting a circular economy, PVC helps reduce the dependence on virgin raw materials and minimizes environmental impact. Manufacturers like Jiangsu Pangrui New Materials Co., Ltd. further enhance this sustainability benefit by providing optimized formula ratios and technical support to ensure high recycling efficiency and product consistency.

Another significant advantage of PVC in sustainable construction is its adaptability through formulation. Using additives such as heat stabilizers, plasticizers, lubricants, pigments, and foaming agents, PVC can be engineered to meet different functional requirements without compromising its environmental performance. For example, lightweight PVC foaming materials reduce the overall weight of construction components, lowering transportation emissions and simplifying installation processes. UV-stabilized PVC materials ensure long-term stability in outdoor applications, reducing degradation and extending service life. This flexibility in formulation allows PVC to meet the evolving demands of modern construction while supporting environmental responsibility.

PVC also plays an important role in improving indoor environmental quality. High-quality PVC materials used in flooring, wall panels, and ceiling applications can be produced with low VOC (volatile organic compound) emissions, contributing to healthier indoor environments. These materials are easy to clean, resistant to mold and bacteria, and safe for sensitive environments such as hospitals, schools, and residential buildings. With growing awareness of the importance of indoor air quality, PVC proves to be a reliable choice for sustainable and health-conscious construction. The use of PVC in green building certifications and eco-friendly construction projects continues to grow globally. Many sustainable building standards, such as LEED and BREEAM, recognize PVC-based solutions for their energy efficiency, durability, and recyclability. As more countries adopt regulations encouraging sustainable building practices, PVC’s role is expected to expand even further.

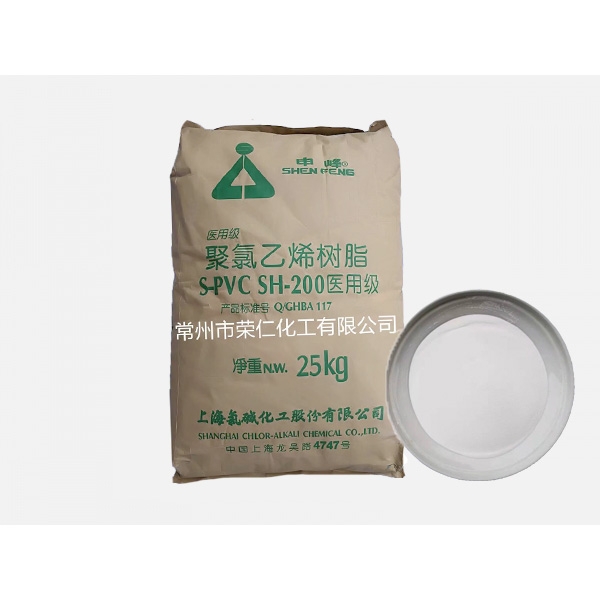

At Jiangsu Pangrui New Materials Co., Ltd., we support this movement by supplying high-quality PVC resin powder, heat stabilizers, pigments, plasticizers, and other essential additives that enable manufacturers and builders to develop more efficient and environmentally friendly construction solutions. With our technical expertise and commitment to innovation, we help partners create PVC materials that not only meet strict performance requirements but also align with global sustainability goals. The future of construction depends on smarter, stronger, and greener materials—and PVC stands at the forefront of this transformation. Its durability, recyclability, energy efficiency, and adaptability make it an indispensable material for sustainable buildings and infrastructures. As industries continue striving for sustainability, PVC will remain a cornerstone of modern construction solutions, supporting the development of cities and communities that are both environmentally responsible and built to last.