How Jiangsu Pangrui Ensures Quality Control at Every Stage of Production

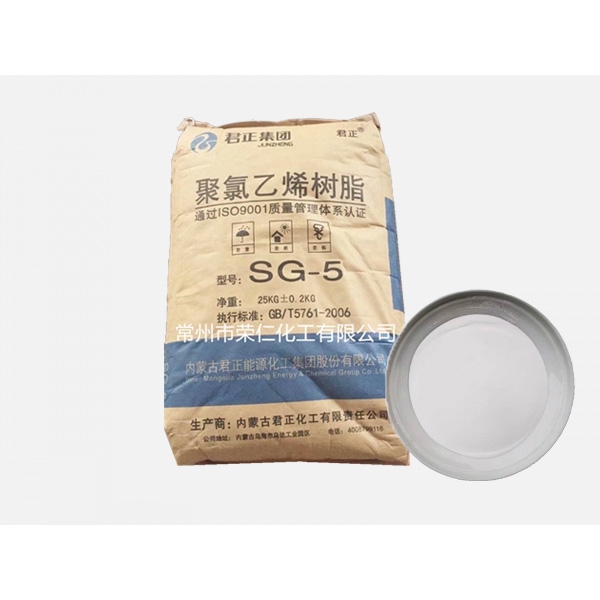

Quality is not an accident—it is the result of systematic control, technical expertise, and a strong commitment to responsibility. At Jiangsu Pangrui New Materials Co., Ltd., quality control is integrated into every stage of production, from raw material selection to final product delivery. As a company specializing in PVC and conductive plastic products, Pangrui understands that consistent quality directly impacts customer productivity, product performance, and long-term trust. That is why a comprehensive, end-to-end quality control system lies at the core of its operations. The first stage of quality assurance begins with raw material selection. PVC resin powder, heat stabilizers, plasticizers, pigments, conductive carbon black, and other additives must meet strict internal standards before entering the production process. Each batch of incoming materials is carefully inspected for physical properties, chemical composition, and performance consistency. By working with reliable suppliers and applying rigorous inspection protocols, Jiangsu Pangrui ensures that only qualified materials are used, creating a solid foundation for stable and repeatable production.

Formula design and verification represent the second critical stage of quality control. PVC and conductive plastic products rely heavily on precise formulation, where even small deviations can affect processing behavior and final performance. Pangrui’s technical team develops and optimizes formula ratios based on application requirements, processing conditions, and customer needs. Before large-scale production, formulas are tested through laboratory trials to evaluate thermal stability, mechanical strength, dispersion quality, and conductivity where required. This pre-production validation minimizes risks and ensures that products perform as expected from the very beginning. During production, strict process control is applied at every step. Processing parameters such as temperature, mixing time, extrusion speed, and dispersion uniformity are closely monitored and adjusted in real time. Standardized operating procedures guide production teams to maintain consistency across batches. By combining skilled technicians with controlled production environments, Jiangsu Pangrui reduces variability and ensures that product quality remains stable regardless of production volume.

In-process inspection plays a vital role in maintaining quality continuity. Samples are taken at different stages of production to assess key indicators such as color consistency, particle dispersion, melt behavior, and physical properties. For conductive plastics, electrical performance and conductivity levels are carefully measured to ensure compliance with application requirements. Any deviation from standard specifications triggers immediate analysis and corrective action, preventing defects from progressing further in the production cycle. Advanced testing methods further strengthen Pangrui’s quality control system. Finished products undergo comprehensive performance testing, including thermal stability tests, mechanical property evaluation, aging resistance, and application-specific simulations. These tests ensure that PVC materials maintain performance under real-world conditions such as heat exposure, mechanical stress, and long-term use. For customers with specialized requirements, customized testing protocols are also applied to ensure full alignment with their production and application environments.

Quality control at Jiangsu Pangrui extends beyond internal processes to include close collaboration with customers. The company provides free samples and technical support, allowing customers to test materials directly in their own production lines. Feedback from these trials is carefully analyzed and used to further refine formulations and processing recommendations. This open communication loop ensures that quality is not only controlled in the factory but also validated in real customer applications. Documentation and traceability are also essential components of Pangrui’s quality management approach. Every batch of materials is tracked through the production process, with detailed records of raw materials, formulations, processing parameters, and test results. This traceability enables rapid problem identification, continuous improvement, and consistent compliance with industry standards. It also provides customers with confidence in the reliability and accountability of Pangrui’s products.

Beyond technical systems, quality control at Jiangsu Pangrui is driven by a strong company culture. The company’s mission emphasizes integrity, responsibility, and long-term trust. Employees are trained to understand that quality is not just a technical requirement but a commitment to customers, partners, and society. Continuous training, internal audits, and process optimization help ensure that quality awareness remains strong at every level of the organization. By integrating strict raw material control, precise formulation, standardized production, thorough testing, and customer collaboration, Jiangsu Pangrui New Materials Co., Ltd. ensures quality control at every stage of production. This comprehensive approach not only guarantees product consistency and performance but also helps customers improve productivity, reduce risks, and enhance competitiveness. As markets continue to evolve and quality expectations rise, Jiangsu Pangrui remains dedicated to delivering reliable, high-performance PVC and conductive plastic solutions built on a foundation of trust and excellence.